Why Quality Control in Dental Labs Is Crucial for Long-Lasting Results

The Importance of Quality Control in Dental Labs for Durable Results

Dental labs play a huge role in modern dentistry, crafting everything from crowns and bridges to dentures and orthodontic devices that boost both patients' health and confidence. But behind every successful dental restoration is a strong quality control (QC) system.

At Summit-Horizon Dental Lab, we know that achieving long-lasting results depends on our commitment to quality at every stage. Let’s dive into why quality control is so essential in dental labs and how it impacts patient outcomes.

Making Sure Everything Fits Right

One of the biggest reasons for quality control in dental labs is to ensure everything fits perfectly. Dental restorations and appliances need to be precise—if a crown, for instance, doesn’t fit well, it can cause discomfort, lead to tooth decay, or even damage nearby teeth.

Using accurate impressions, precise milling, and advanced technology is key to crafting restorations that fit comfortably and work properly.

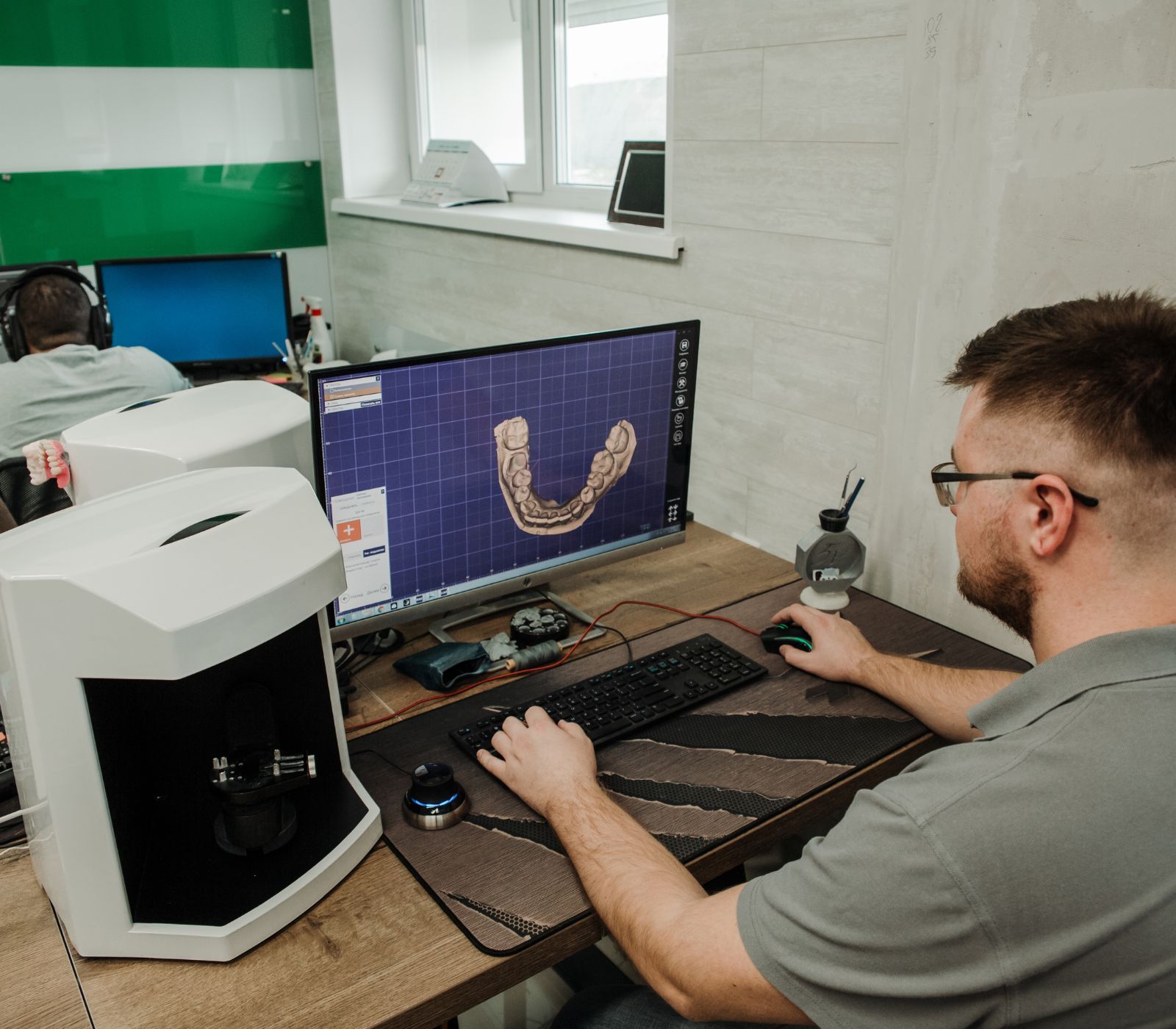

At Summit-Horizon Dental Lab, we have a rigorous QC process to check that every restoration meets precise measurements before it gets to the dentist. By using CAD/CAM technology, we create digital models, allowing us to spot and fix any issues early on. This means that the products we deliver fit well, ensuring patient comfort and satisfaction.

Using High-Quality Materials

Quality isn’t just about precision; it’s also about using the right materials. Dental restorations face constant pressure from chewing, grinding, and temperature changes. If we use low-quality materials, the restorations could crack, change color, or wear down quickly, leading to repeat visits for repairs or replacements.

Our quality control process at Summit-Horizon Dental Lab involves carefully checking the quality and authenticity of every material we use. We work with trusted suppliers to ensure our ceramics, metals, and polymers meet industry standards for safety, strength, and aesthetics. By choosing the best materials, we create restorations that are not only durable but also safe for patients, reducing the chances of problems or complications.

Keeping Products Consistent

Consistency is a crucial part of quality control. Dental professionals and patients depend on labs to deliver restorations that look and perform consistently. If a lab produces crowns or bridges that vary in color, shape, or strength, it can cause frustration and lead to more dental work.

At Summit-Horizon Dental Lab, we maintain consistency by standardizing our processes and using advanced QC systems. From the moment we receive an impression to the final inspection, we follow strict protocols to minimize variability. Our digital workflows also allow us to replicate successful designs precisely, ensuring that our products consistently meet the high standards our clients and their patients expect.

Catching Mistakes Early and Reducing Remakes

Even though dental restorations need to be precise, mistakes can still happen. Without a solid QC system, errors like incorrect measurements or defects in materials might not be caught until the product is delivered to the dentist. These mistakes not only waste time and resources but also lead to patient frustration when things need to be redone

That’s why it’s so important to have a strong quality control process in place to catch and fix errors before products leave the lab. At Summit-Horizon Dental Lab, our technicians conduct thorough inspections throughout the production process. Plus, with digital scanning and CAD/CAM technology, we reduce manual errors and improve precision. By identifying issues early, we minimize the need for remakes and ensure our clients get high-quality products that meet their needs the first time.

Staying Compliant with Industry Standards

Dental labs have to follow a variety of industry standards and regulations to make sure their products are safe and high-quality. Standards from organizations like the International Organization for Standardization (ISO) and the FDA set guidelines for the best practices in manufacturing and QC for dental restorations. Complying with these standards not only builds credibility for the lab but also protects patients from the risks that come with poorly made products.

Summit-Horizon Dental Lab is committed to meeting and exceeding these standards. Our QC system is designed to align with ISO and FDA requirements, so we know every product we create is safe, durable, and effective. By sticking to these regulations, we show our dedication to delivering high-quality restorations that provide long-lasting benefits for patients.

Building Patient Satisfaction and Trust

The ultimate goal of any dental lab is to create restorations that make patients happy. When people invest in dental work, they expect it to last, be comfortable, and look good. If a lab doesn’t prioritize quality, patients might end up with restorations that cause discomfort or don’t look right, affecting their confidence and oral health.

At Summit-Horizon Dental Lab, we know our products make a difference in people’s lives. By sticking to strict quality control measures, we make sure every restoration not only looks natural but also functions well, giving patients the comfort and durability they expect. This dedication to quality helps build trust with our partner dental practices, as they know they can count on us to deliver results that meet or exceed patient expectations.

Supporting the Relationship Between Dentists and Patients

The quality of a dental lab’s work directly impacts the relationship between dentists and their patients. Dentists who partner with labs that consistently deliver quality restorations can confidently recommend treatments and build strong relationships with their patients. But if a lab’s products often require adjustments or remakes, it can hurt that trust and lead to patient dissatisfaction.

By prioritizing quality control, Summit-Horizon Dental Lab helps dentists provide top-notch care. Our partners trust that our restorations will fit perfectly, function well, and maintain their aesthetic appeal. This reliability helps dentists maintain a strong reputation and encourages patients to return for ongoing care, contributing to the long-term success of their practices.

Cutting Costs and Boosting Efficiency

While quality control might seem like an extra cost, it saves money in the long run. By reducing errors, ensuring consistency, and creating long-lasting restorations, dental labs can cut down on the need for remakes, adjustments, and replacements. These savings benefit both the lab and its partner practices, leading to better efficiency and profitability.

At Summit-Horizon Dental Lab, our focus on quality control allows us to streamline production, minimize waste, and improve turnaround times. By investing in technology and training, we create efficiencies that help our clients provide affordable and timely services to their patients.

Conclusion

Quality control is the foundation of any successful dental lab. It ensures precision, consistency, and safety while enhancing patient satisfaction and trust. At Summit-Horizon Dental Lab, we take quality control seriously, following rigorous protocols to deliver high-quality, long-lasting restorations. By doing so, we support the success of our partner dental practices and contribute to the health and well-being of the patients they serve. When quality is the priority, everyone wins, and the results speak for themselves.

Share Post

Search Post

Recent Insights